Photoresist / Photolithography - A Chemical Substance That Becomes Insoluble By Exposure To Ultraviolet Light

Photoresist is a light-sensitive chemical substance that is used to form a coating on a surface or substrate and is used to form patterns for industrial processing. This coating can then be exposed to a specific band of light, referred to as the photoresist’s action spectrum, to affect a desired change in the photoresist. This change causes the photoresist to either become soluble or insoluble to another chemical called the developer which will be washed over the photoresist.

Once developed, the photoresist that has been exposed to light in the action spectrum either remains or is washed away leaving a pattern that can then be used for further processing such as chemical etching, engraving, or lithography.

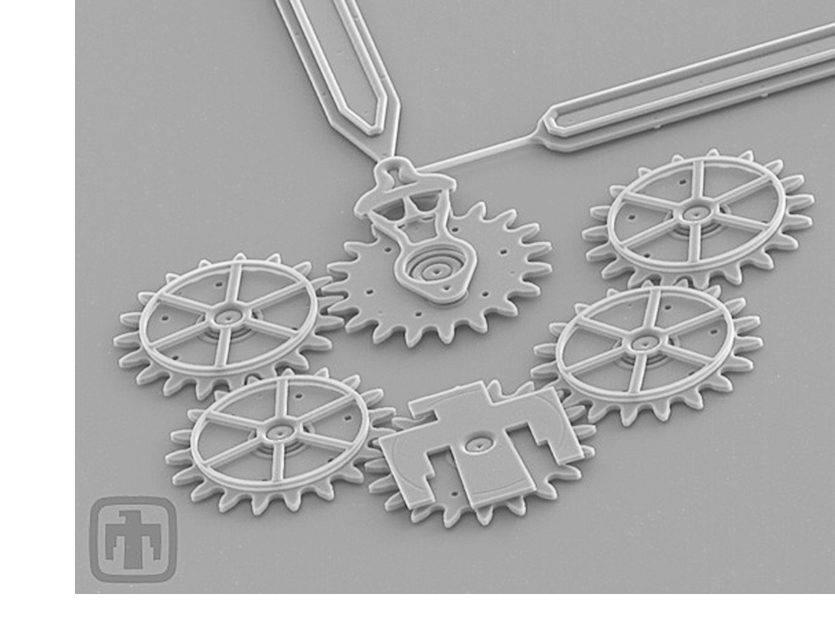

Photoresist / Photolithography sees widespread use in numerous technologies including micromachining

Photoresist/Photolithography is extensively used in the printed circuit board industry where the patterns created by its use layout the circuit connections or traces of printed circuit boards through the use of etching chemicals.

Another heavy user of photolithography and photoresist is the semiconductor industry, where it is a crucial step in the photolithographic production of micro-patterns that are used to form the tiny circuits of individual semiconductor devices.

Photoresists have also found use in Biomedical engineering, holography, and micromachining. The last application, micromachining, is a rapidly advancing arena in industrial technology.

Also referred to as MEMS, short for Micro-Electro-Mechanical Systems technology, micromachining has driven the use of photoresist to remarkable new heights. Special photoresists and substrates are carefully processed and developed repeatedly in micro-sized layers, forming fully functional micro-sized circuits, structures, and even entire machines such as gear sets, valves, mirrors, sensors, and gyroscopes. Some MEMS devices can be as small as a single micrometer.

DLP or digital light processing is a technique used in modern projection television sets that utilizes a microchip with thousands of microscopic mirrors on its surface, manufactured through MEMS technology, along with a light source to create smooth, high-contrast, jitter-free images.

Controlling the exposure of photoresists is critical to maintaining production

Many photoresist types exist to suit a large variety of applications, and the action spectra can vary from one to the next. It is critical to control the action spectra exposure settings, both the intensity of the light and the time of exposure, to avoid wasteful under or overexposure of the photoresist during processing and production.

To maintain these settings, a light meter with a spectral response as close to the photoresist’s action spectrum as possible is required to get an accurate idea of how well the photoresist is being exposed. Further complicating matters is the processing equipment where photoresists are exposed are frequently very compact and have minimal room for taking these measurements.

International Light Technologies is committed to providing a variety of unique, photoresist-specific instruments to assist our customers in making these often difficult measurements.

Selecting a System

ILT meters come with NIST traceable, ISO/IEC 17025:2017 Accredited calibrations in units of Watts, Lumens, Watt/cm2, lux and foot-candles as well as full spectrum analysis.

Input optics, including small cosine receptors, integrating spheres, narrow beam adapters and apertures (for testing uniformity) can be added to ILT systems making them the most versatile systems available.

ILT engineers and technical support staff are available to customize systems to the unique requirements of our customers.

Use the table below to identify the system (meter + detector) that meets your specific application. Use the table to find the spectral range you wish to measure. The table can be filtered to show our meters by type, (e.g., hand-held), as well as searching on the minimum and maximum spectral range you wish to measure. The tables can also be sorted to group systems by meter type, spectral range, measurement range, and units. Click the product link of the system to view it's details.

Need assistance? Contact us using the form below, or by calling us at 978-818-6180.

* All Radiometers/Photometers/Spectroradiometers are NIST Traceable.

* If units of measure are not shown please contact us (empirical units also available i.e.fc, fL, nits, lm/ft²).

Image courtesy of Sandia National Laboratories, SUMMiTTM Technologies, mems.sandia.gov

Explore All Light Meters By Application Type

- Germicidal UV Radiometers & Spectrometers

- UV Curing Light Measurement Systems

- Audience Scanning Radiometers & Spectrometers

- Endoscopic System Light Meters

- Pulsed Light Measurement Systems

- Low Light Level Lux Meters

- Low Light Level Measurement

- Optical Radiation Hazard Light Meters

- Photodynamic Therapy Radiometers & Spectrometers

- Photometric Spectral Light Meters

- Photoresist Radiometers & Photometers

- Photostability UVA Detectors

- Phototherapy Light Meters & Radiometers

- Plant Photobiology & Photomedicine Light Meters

- Radiometry Light Meters

- Solar Radiation Light Meters