Do I need to re-calibrate my light measurement system (light meter)?

Let’s start by saying the real question is not “if” you need to calibrate, but “when” or how frequently you need to calibrate.

Calibrating your light meter is necessary, as the accuracy of the measurements drop over time and can eventually lead to an out-of-tolerance condition. However, for many applications the shift is minor and with proper maintenance and record keeping, an effective and efficient calibration cycle can be determined and maintained.

To determine the “when” you must determine the following:

-

Are you taking critical measurements?

-

Are you publishing data?

-

Are you troubleshooting a problem that effects product quality or yield?

-

Are you working over a very broad range of sensitivities?

-

Are you working in harsh environments that would increase the risk of damage or degradation?

-

Are you required by your own quality department, a customer specification, or regulatory compliance to calibration at specific intervals and to a certain standard?

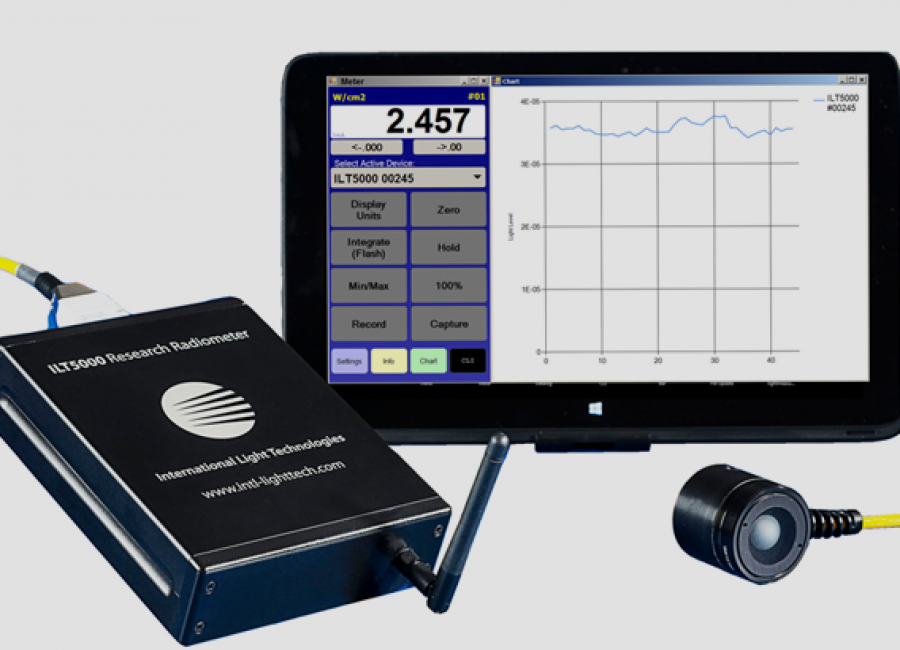

Most light measurement systems include a meter that measures current or voltage, and a light sensor that consists of a photodiode, filtration and an input optic. Some meters offer auto ranging over a broad range, or have a range selection feature. Meters with broader dynamic ranges and higher levels of sensitivity, typically require more timely adjustment to the zero and calibration of the electronics, especially at the lower sensitivity ranges. Major components of instruments like voltage references, current shunts and input dividers can become noisy or experience a zero drift over time. Calibration can ensure that both high and low light levels are being properly measured, and linearity is maintained.

Optical sensors are often exposed to a variety of temperatures, light intensities, and spectrum, ranging from UV to IR. The sensor and their optical components can become dirty, discolored, damaged and experience photodegredation. Multilayer or coated filters can delaminate or experience change in transmission. Components can increase, decrease or experience spectral shifts in sensitivity causing readings to change that do not directly relate to the changes in light output.

Because of these known risks, most light meter suppliers will start with a recommendation for an annual calibration, and provide an allowable tolerance for change during the recommended calibration cycle. Units that are found in tolerance or showing little/no change can safely have their calibration interval extended. Units that have experienced damage, wear, or out-of-tolerance conditions are often recommended for a shortened calibration cycle.

For a select few applications, such as transmission and reflectance, there is only a limited benefit to calibration. Meters used for these types of measurements typically allow the user to reset the 100% range based on their light source intensity during each test, and may in fact not benefit from frequent calibration. However, if the accuracy of the results could be impacted by the linearity of the system, periodic calibration of the electronics may still be in order.

ILT typically recommends that our light meters begin with an annual calibration. Once the annual change is evaluated, or based on the history of similar products, the customer can then choose their own interval.

Below are some instances where an organization may choose to calibrate their equipment:

1. Before a critical measurement, e.g., testing a new curing lamp prior to the roll out of a new product line

2. After a critical measurement, e.g., after project is complete you may need to validate the systems performance. Calibration will confirm the test device did not change during the critical project.

3. Possible damage, e.g., a meter or sensor were dropped, shocked, over heated, over exposed, or submerged/covered by liquid.

4. Supplier/customer requirements, e.g., customer requires all systems are validated with in 3 months of testing.

5. Periodically based on quality records. This could be monthly, quarterly, bi-annually, annually or every 2-3 years. Keeping good records of the quality of your system can calibration call allow you to create the best cycle.

6. Never. If your device is use to compare two like items, measure small changes in reflectance or transmission, and is always properly cared for and records maintained, it may never require calibration or adjustments.

ILT offers ISO/IEC 17025:2017 Accredited and NIST Traceable calibrations of many types and brands of light meters. To learn more about the calibrations we offer, fill out the contact form at the bottom of the page, or visit our Calibration page here.