UV-C LEDs for UVGI / Disinfection

In order to support disinfection efforts for COVID 19, omicron variant, and other UVGI requirements we are currently stocking UV LED’s for 275 nm in a variety of packages for design and development as well as one complete light source (UV LED module with heat sink, power supply, cooling fan and power cord).

Our UVC LEDs are rated as 275 nm (270 - 280 nm) wavelength and they are available in few different power levels and styles. Choose from single, chip-on-board, strip, to complete light source module using the specification chart below. Volume pricing is available for all items noted in the chart below. Longer strip lengths with higher outputs are also available. Lead time will vary by product ranging from 1-6 weeks depending on the item selected and volume required.

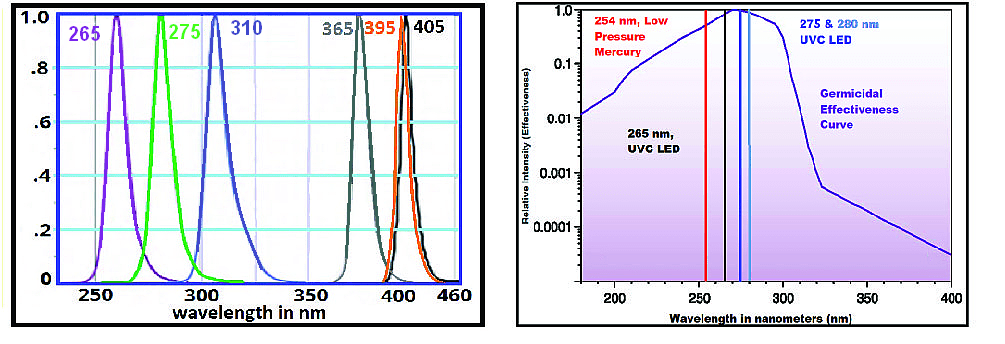

LED's have been increasingly used in applications where UV lamps (mercury, xenon, amalgam, excimer) have operated for decades. Improvements in UV-LED flux density, stability and life hours have made UV LEDs a viable solution for replacing traditional UV light sources such as mercury arc lamps, arch lamps, hot and cold cathode lamps, and grid lamps. UV LEDs are more environmentally friendly as they do not contain harmful mercury, do not produce ozone, and consume less energy. Use of UV-C LEDs is rapidly growing in applications such as germicidal (UVGI) for air, surface and water purification.

Note: Other wavelength LED’s are also available including 310 nm, 365 nm and 405 nm (UVA and UVB). Minimum buy and lead times will vary, but typically start at 25 pcs and 2-3 weeks. Please contact customer service with your wavelength and quantity to receive pricing and lead times.

|

Image (click for larger image) |

Part # Click for Specs or to Buy |

Type | Peak Wave- length nm |

Radiant Flux |

Voltage |

Constant |

Dimensions LxWxH |

Min Order |

Price Each |

Data Sheet | Request Volume Price or Additional Information |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

E275-3 | Bare chip | 275 | 3 - 6 mW | 5 - 7 V | 40-50 mA |

3.45 x 3.45 x 1.3 (+/- 0.2) |

Pks of 5 |

$15.73 | Contact Us | |

|

E275-3-S | Chip on star board | 275 | 3 - 6 mW | 5 - 7 V | 40-50 mA |

20 x 20 x 3.2 | Pks of 5 |

$16.85 | Data Sheet | Contact Us |

|

ILT-PWRTYLED .3W | LED Driver* | N/A | N/A | N/A | N/A | N/A | 1 | $21.91 | N/A | Contact Us |

|

E275-10 | Bare chip | 275 | 10 - 18 mW | 6 - 7 V | 100-150 mA | 3.45 x 3.45 x 1.3 (+/- 0.2) |

Pks of 5 |

$38.20 | Contact Us | |

|

E275-10-S | Chip on star board | 275 | 10 - 18 mW | 6 - 7 V | 100-150 mA | 20 x 20 x 2.9 | Pks of 5 |

$42.14 | Data Sheet | Contact Us |

|

|

E275-60-Strip |

UVC LED Strip 60 x 20 mm |

275 | 20 - 30 mW | 12 V | 200 mA | 60 x 20 x 3.8 | 1 | $77.52 | Contact Us | |

|

|

ILT-PWR-12600P5 | LED Driver** | N/A | N/A | N/A | N/A | N/A | 1 | 23.59 | N/A | Contact Us |

|

|

E275-80-Module | 20 LED UVC Module | 275 | 80 - 100 mW | 10 - 15 V | 600 mA | 78 x 68 x 68 | 1 | $448.28 | Contact Us |

* The ILT-PWRTYLED.3W driver is compatible with the E-275-3 and E-275-3-S 3-6 mW LEDs only.

** The ILT-PWR-12600 driver is compatible with the E275-60 Strip only. Powers up to 2 strips.

UV LED Applications

International Light Technologies offers UVC LEDs for a variety of applications and uses. Our UV LEDs are effective against eliminating harmful bacteria, fungi, and viruses such as COVID-19. Below are some of the most common applications our products can be used in:

- Germicidal (UVGI) purification

- Air Purification

- Surface Sterilization

- Water Disinfection

- Hospital Sanitization

Get in touch with us today to discuss your requirements so we can provide you with a consultation best suited to your needs.

Browse Light Sources By Category:

UVA and UVB LEDs

VIS-IR, Miniature and Precision Lamps

Tungsten Halogen & Gas Filled Lamps

Neon Lamps

Reflector Lamp Assemblies

Through Hole LEDs

Surface Mount LEDs

Lamp Holders

Line Filament Lamps

Replacement / Custom Lamps

Click Here To View Our Configured UVGI Light Measurement Systems

UV-C LED Frequently Asked Questions

What are UVC LEDs?

UVC LEDs belong to the category of light-emitting diodes that produce ultraviolet light within the UVC wavelength band (200-280 nanometers). The emitted UVC light is recognized for its capacity to inactivate bacteria, viruses, and various other microorganisms.

What are the benefits of using UVC LEDs over traditional UV lamps in disinfection applications?

UVC LEDs offer numerous benefits over traditional UV lamps in disinfection applications, including:

- Extended longevity: UVC LEDs are capable of lasting up to 25,000 hours, a significantly longer duration compared to traditional UV lamps, which generally have a lifespan of only 6,000 to 9,000 hours.

- Enhanced energy efficiency: In comparison to conventional UV lamps, UVC LEDs demonstrate superior energy efficiency.

- Safety: UVC LEDs are safer to use than traditional UV lamps because they do not contain mercury or produce ozone.

Can UVC LEDs be used for water purification?

Yes, UVC LEDs can be used for water purification to inactivate bacteria, viruses, and other microorganisms that can cause waterborne diseases.

Are UVC LEDs effective against all types of bacteria and viruses?

UVC LEDs are effective against E. coli, Salmonella, Listeria, Legionella, Staphylococcus aureus, COVID-19, influenza, norovirus, among others.

Can UVC LEDs be used for food and beverage processing and preservation?

Food and beverage processors are increasingly using UVC LEDs to disinfect surfaces and reduce the risk of foodborne illness. UVC LEDs inactivate harmful bacteria and viruses by damaging their DNA, preventing them from reproducing.

When choosing UVC LEDs for a specific application, it is important to consider the following factors:

- The type of microorganisms that need to be killed: Different microorganisms have different sensitivities to UVC light. It is important to choose UVC LEDs with a wavelength and intensity that are effective against the specific microorganisms that you are targeting.

- The size and shape of the area to be disinfected: UVC LEDs emit light in a directional beam. The shape along with the size of the area requiring disinfection will determine the number and placement of UVC LED fixtures.

- The intensity of UVC light required: The intensity of UVC light required will vary depending on the type of microorganisms to be inactivated, and the distance from the UVC LED fixture to the surface being disinfected.

- The desired lifespan and energy efficiency of the UVC LEDs: UVC LEDs have a lifespan of up to 25,000 hours. However, the intensity of UVC light emitted by LEDs will decrease over time. It is important to choose UVC LEDs with a lifespan and energy efficiency that meet your needs.

- The safety requirements of the application: UVC light can be harmful to human skin and eyes. It is important to install UVC LED fixtures in a way that avoids exposure to humans.

What are the main factors to consider when choosing UVC LEDs for a specific application?

When choosing UVC LEDs for a specific application, you need to consider the following factors:

- The type of microorganisms you need to eliminate

- The size and shape of the area you need to disinfect

- The intensity of UVC light required

- The desired lifespan and energy efficiency of the UVC LEDs

- The safety requirements of the application

Can UVC LEDs be used for mold and mildew control in residential or commercial settings?

Yes, UVC LEDs can be used for mold and mildew control in residential and commercial settings by killing mold and mildew spores, preventing the growth of these harmful fungi.

How do UVC LEDs compare to traditional UV lamps in terms of energy efficiency and environmental impact?

UVC LEDs are a more sustainable and energy-efficient alternative to traditional UV lamps for disinfection applications. They consume less power, produce less heat, and do not emit harmful mercury vapor or ozone.

How are UVC LEDs used in hospital sanitization?

UVC LEDs are used in a variety of ways in hospital sanitization, including disinfecting medical devices and equipment, air and surface disinfection, and water purification.

How effective are UVC LEDs for surface sterilization?

UVC LEDs are very effective for surface sterilization, with studies showing that they can kill up to 99.99% of bacteria and viruses on surfaces.